Effective moisture absorbers for containers

- Varied range of quality container moisture absorbers for sea cargo and container freight

- Desiccants suitable for transport and storage

- Constituents: Calcium chloride and starch (does not contain DMF)

- Designed to be quick and easy to handle and place

- Fitted with sturdy hooks or adhesive strips for secure placement

- Certified German quality

- Delivered direct from our German warehouse

- Priority shipping available

How using moisture absorbers for containers prevents expensive damage

Goods transported in containers by ship or freight train frequently undergo huge fluctuations in temperature. These fluctuations often lead to large amounts of moisture forming within the freight container. Condensation also occurs when goods are stored in containers, due to the difference in day and night temperatures. Moisture absorbers for containers control moisture levels and protect against moisture damage. Specially produced hygroscopic, or water-attracting materials wrapped in secure water vapour-permeable packaging can be placed on the container walls or directly on the cargo itself. It’s easy and fast to hang our container moisture absorbers from container eyelets or they can be glued onto the outer packaging of the goods.

Which container desiccant for which application?

To ascertain which desiccant is right for your needs, you would require a needs analysis to be undertaken. We can do this for you to analyse your situation and advise you which container desiccant you need, as well as the amount required and how to place it optimally in the container.

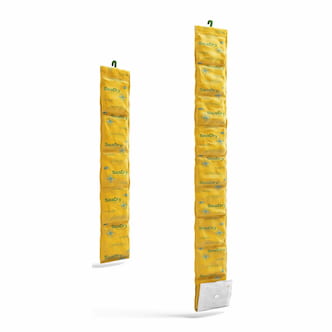

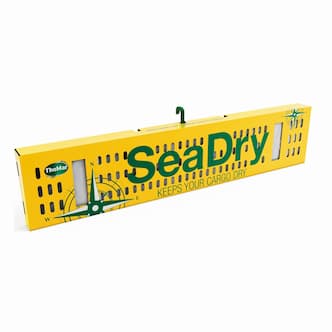

SeaDry Hook moisture absorbers come with integrated hooks for easy attachment to container eyelets. Suspending these desiccants against the container walls ensures they’re optimally placed to absorb any internal humidity. They also have adhesive strips on the sheathing materials which allow their attachment to other locations if required.

These moisture absorbers are designed for container use and can be hooked into the eyelets directly beneath the container ceiling where the risk of condensation is highest. Placing container desiccants at ceiling height also permits trouble-free loading and unloading of the container.

This compact product can be distributed in almost any gap in tightly-packed containers. SeaDry Singles have adhesive strips so can be attached directly to the packaged goods, stowage material or container wall.

A moisture absorber consisting of a multi-layer film and a HDPE (high-density polyethylene) fleece. Its adhesive strip makes it especially suitable for cramped spaces or where there’s nowhere to hang desiccant (e.g. no tie-down eyelets), for example, in refrigerated containers. SeaDry Strips have an adhesive strip on the back and can be attached to the goods or to the container wall.

The SeaDry desiccant blanket is an ideal solution where large quantities of moisture need to be absorbed. Each SeaDry Blanket has an absorption capacity of more than three litres of water. In the case of tightly-packed containers, the blanket can simply be laid on the packed goods during container loading.

ThoMar's end-to-end service

As a manufacturer of moisture absorbers, we offer our customers end-to-end service to ensure their goods are protected against cargo damage from moisture in containers. Our comprehensive service includes: ● Precise needs analysis ● Tailored advice ● Desiccant product selection ● Bespoke advice Here’s a detailed look at each stage of our customer service:

Analysis: Determining desiccant requirements

There are many factors involved in determining the type and quantity of moisture absorber that you need. These are analysed by our experts and include the: ● goods to be transported ● climate zones on the route ● container size ● weight and moisture content of the goods ● packaging aids used ● duration of storage/ transportation and other parameters.

Consulting: A bespoke service

Our English-speaking expert team is available to you from Monday to Thursday 8:00 am–4:00 pm, and on Fridays from 8:00 am to 3:00 pm (UK time) by telephone on +49 (0)4153 55900-0. Get in touch if you need: ● general advice on shipping container desiccants ● support in analysing the individual requirements for your application ● guidance on selecting the right desiccants

Training on attaching and placing container moisture absorbers

After your requirements have been determined and the right products, they then need to be attached correctly and distributed optimally. Our experts advise the employees of our customers via personal training sessions on handling desiccants so you enjoy the best possible results.

Made in Germany: Certified quality from the Duchy of Lauenburg, near Hamburg

Management ThoMar OHG (from left): Thomas Möller, Daniel Schuback, Martin

Möller

ThoMar OHG has been producing and trading desiccants for more than 20 years. We produce our moisture absorbers for use in containers exclusively at our German headquarters and factory located in the Duchy of Lauenburg region near Hamburg. We observe the highest standards with regard to desiccant constituents, sheathing materials, product quality, and employee health and safety. We supply industry and the wholesale trade directly ex works. ThoMar OHG has been ISO 9001-certified since 2012 for the development, manufacture and distribution of desiccant bags and air dehumidifiers. Smaller quantities of desiccants can also be ordered in our B2B online shop.