- Home

- Container & Transport

Dehumidification without hermetic sealing

ThoMar as a reliable partner for the public sector

Various supply centres, battalions and service centres have already been impressed by the effectiveness and practicality of our SeaDry container desiccants manufactured in Germany. In particular, the SeaDry Pole Horizontal 1,200 g product variant is regularly used by various organisations in containers used as storage rooms and also in vehicles. And the SeaDry Blanket 1,500 g product variant, which can be placed directly on packaged goods and merchandise, has repeatedly been used for moisture protection during container transport.

Corresponding supply articles for the German armed forces are listed under the NCAGE code CM866:

- SeaDry Pole Horizontal 750g, with hook, hangs horizontally, with protective casing

(VersNr 6850-12-394-2721 / Teilekennzeichen 6850-0071-5) - SeaDry Pole Horizontal 1,200g, with hook, hangs horizontally, with protective casing

(VersNr 4440-12-415-8933 / Teilekennzeichen 6850-0071-8) - SeaDry Pole Horizontal 1,500g, with hook, hangs horizontally, with protective casing

(VersNr 6850-12-394-2722 / Teilekennzeichen 6850-0071-4) - SeaDry Pole Vertikal 1,000g, with hook, hangs vertically, with protective casing

(VersNr 4440-12-415-8934 / Teilekennzeichen 6850-0071-9) - SeaDry Pole Vertikal 1,200g, with hook, hangs vertically, with protective casing

(VersNr 4440-12-415-8935 / Teilekennzeichen 6850-0071-10) - SeaDry Hook 1.200 g, with hook, hangs vertically, with adhesive

(VersNr 4440-12-409-9690 / Teilekennzeichen 6850-0071-7) - SeaDry Single 125 g, bag, compact dimensions

(VersNr 4440-12-415-8937 / Teilekennzeichen 6850-0071-12)

(VersNr 6850-12-394-2705 / Teilekennzeichen 6850-0071-1) - SeaDry Single 125 g, ADH, bag, with adhesive, compact dimensions

(VersNr 4440-12-415-8936 / Teilekennzeichen 6850-0071-11)

(VersNr 6850-12-394-2713 / Teilekennzeichen 6850-0071-2) - SeaDry Strip 750 g, ADH, chain, with adhesive, flexible positioning

(VersNr 6850-12-394-2717 / Teilekennzeichen 6850-0071-3) - SeaDry Blanket 1.500 g, blanket, lies directly on the goods / packaging

(VersNr 6850-12-394-2641 / Teilekennzeichen 6850-0071-6)

SeaDry is available in various shapes and sizes to suit your specific application.

ThoMar supplies public authorities with desiccants.

Moisture protection for sensitive electronics during transport

Challenge: High humidity during long-distance transport

During the transfer, which took a good 8 weeks in total, the container travelled through various climate zones with fluctuating temperatures and humidity levels. This posed a considerable risk to the loaded electronics, as even humidity levels above 50% can lead to corrosion damage to cables and components. The customer was looking for a solution to keep the relative humidity constantly low and thus ensure the functionality of the electronics. The packaging components also needed to be protected.

Solution: Combination of SeaDry and in-box desiccants

The company decided to use SeaDry Hook 1200g for protection. The desiccant was attached to the lashing eyes on the container walls to prevent condensation. In addition to this load securing measure for the entire container, inbox desiccants were integrated within the packaging on the pallets to ensure maximum moisture protection.

Result: Safe transport and complete protection of the electronics

The combined use of SeaDry plus inbox desiccant proved its worth - moisture was kept at a safe level throughout the entire transport. Both the electronic components and the packaging materials arrived at their destination without any damage. The economical use of SeaDry container desiccants was particularly convincing, as just 10 of them per 40-foot container were enough to reliably protect the entire load.

SeaDry protects electronics from moisture damage

Protecting textile goods during transport by container

Challenge: Moisture-sensitive textiles without individual packaging

The textiles were covered with foil in the cardboard packaging, but not individually packed in polybags. The customer's original idea of adding silica gel bags to the cartons turned out to be unsuitable, as silica gel is only effective in airtight packaging.

Solution: Use of SeaDry high-performance desiccants

ThoMar recommended the use of SeaDry Single 125g bags. These high-performance desiccants absorb seven times as much moisture compared to Silica Gel, providing optimum protection during the long sea journey.

Result: Prevention of moisture damage to textiles

By using SeaDry, moisture damage was avoided and the goods were delivered to the recipient safely and in perfect condition. This led to a high level of customer satisfaction and long-term confidence in the use of SeaDry for future shipments.

SeaDry protects textiles from moisture damage

How to protect relocation goods from moisture damage with desiccants

Challenge: Moisture protection for moving goods over long transport distances

Wood and upholstered furniture, metal kitchen equipment, electronic devices, clothing, shoes, decor, and artwork must be securely protected from moisture, mold, rust, and odors during transport. An effective yet simple solution is required, especially for long-distance journeys.

Solution: The ThoMar checklist for effective moisture protection for moving goods

Here are some recommendations to ensure that your start in dreamland is not spoilt by mould, rust, mildew stains and a musty smell when you open the container.

- A combination of a high-performance desiccant (here: SeaDry on a salt-starch basis) - for use in the container - and a so-called inbox desiccants (here: CertiDry in accordance with DIN 55473 / contains clay granules) - for use inside the moving boxes - offers the best protection.

- Use packaging materials, such as moving boxes, in as dry a state as possible. Paper / cardboard binds moisture depending on the ambient climate; if necessary, dry in the boiler room beforehand.

- Line moving boxes with sturdy plastic film bags / bin liners, for example. Place the packaged goods together with CertiDry desiccant in accordance with DIN 55473 (type A, 4 DU or 8 DU, 1-2 bags per box). Seal the bags (squeeze out the air first) and moving boxes. Tape up the handle holes so that no further moist air can get in.

- Equip the container with SeaDry container desiccant before loading; the SeaDry Pole H 1.2 kg variant is particularly suitable for this application. Simply mount each piece with its hook on the lashing eyes along the long sides of the container (10 pieces per 20-foot container / 20 pieces per 40-foot container). Overseas shipments by private individuals often take three months or longer. With this amount of SeaDry, the removal goods remain safely protected until arrival.

- Place another box of unused SeaDry Pole H in the container. After arrival, check the saturation status of the suspended desiccants (check by weighing: one SeaDry Pole H is saturated at a weight of approx. 3.6 kg). If the house or flat is not yet ready for occupancy on arrival and the load has to remain in the container for longer, use additional SeaDry desiccants if necessary.

- All desiccants can be disposed of in the residual waste after your relocation project is completed.

SeaDry desiccants for containers and CertiDry desiccants in accordance with DIN 55473 are available in the ThoMar webshop or at Amazon.

Protect your household contents from damp when moving

Protect timber from moisture during transport

Challenge: Rising moisture levels during transport and storage

Our customer shipped kiln-dried sawn timber with an initial moisture content of 8–12%. After four weeks, the timber arrived with moisture levels of up to 45% due to the highly variable humidity inside the container during transport. The reason: timber naturally seeks equilibrium moisture and adjusts its own water content to match the surrounding climate. The beams positioned on the outside of the transport racks had absorbed particularly high amounts of moisture.

Solution: SeaDry as a high-performance desiccant for containers

To prevent moisture-related damage – such as the development of wood-destroying fungi – and avoid resulting complaints from recipients, the high-performance desiccant SeaDry, developed specifically for container use and manufactured by ThoMar in Germany, offers a simple and reliable solution. It provides effective moisture protection for both solid timber and engineered wood products during transport and storage.

Result: Controlled wood moisture and reliable product quality

Several timber-processing companies already use SeaDry successfully in their logistics processes. In the case described, the humidity remained within a safe range thanks to the use of SeaDry. The available standard formats, sizes and mounting options can be found in the SeaDry shop category. With our broad desiccant range, additional process steps and applications can also be reliably covered.

Sawn timber is also transported in containers

Protect special glass transports in containers from moisture

Challenge: Moisture damage to packaging components and auxiliary materials

At one of our customers, the resulting condensation led to mould growth on the wooden packaging components – which in turn caused a justified complaint from the recipient. In more severe cases, customs authorities may even refuse to release a container if packaging materials show visible mould. Moisture therefore poses not only quality and hygiene issues, but also logistical and financial risks.

Solution: Use of SeaDry high-performance desiccants in containers

To reliably prevent moisture-related damage to valuable glass products throughout the entire transport period, the high-performance desiccant SeaDry for use in containers, developed specifically for container use and manufactured by ThoMar, offers a proven and dependable solution. It binds large amounts of moisture and effectively prevents the formation of condensation.

Result: Protection against condensation with versatile application options

Several glass manufacturers already use SeaDry successfully in their logistics processes. The container desiccant is equally suitable for protecting porcelain, ceramic and enamel products during transport and storage. With various formats, sizes and mounting options available, SeaDry can be integrated flexibly. In addition, our broad range of desiccants allows further process steps and applications to be reliably covered.

Architectural and other special glass is also transported in containers

Prevent moisture damage to paper rolls during container transport

Challenge: Moisture absorption and loss of quality during transport

At one of our customers, condensation forming inside the container resulted in soaked sections on several paper rolls. These had to be removed before further processing at the recipient’s site in China – causing additional time, material loss and costs. Paper absorbs moisture extremely quickly and immediately loses its processability; even small damp areas can compromise entire roll batches.

Solution: Absorption of container humidity with SeaDry

To protect sensitive paper rolls throughout the entire transport period, the use of the high-performance SeaDry container desiccant, developed specifically for container applications and manufactured in Germany, is recommended. It sustainably reduces humidity inside the container, prevents condensation even on long transport routes exceeding 60 days, and effectively protects hygroscopic paper rolls from moisture damage.

Result: Dry paper rolls and reliable quality at the destination

Numerous companies in the paper and packaging industry already use SeaDry successfully in their global logistics chains. In the case described, moisture ingress was also reliably prevented. With various formats, sizes and mounting options available, SeaDry can be flexibly adapted to any transport configuration. In addition, ThoMar’s broad desiccant portfolio reliably covers further production and logistics steps.

Paper rolls are transported in freight containers

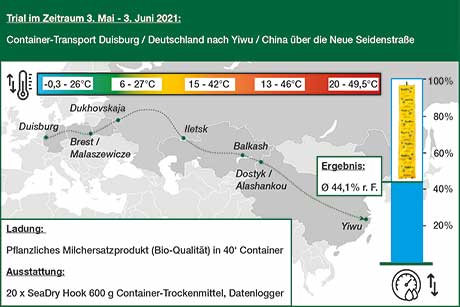

Securing container transports on the New Silk Road against moisture

Challenge: Extreme climate fluctuations along the 10,000 km route

Unlike by sea, where the position of the container determines how exposed the cargo is to the elements, by rail the conditions are the same for all containers. The New Silk Road runs for a good 10,000 km not only across national borders, but also through different climate zones. Extreme temperature fluctuations and thus equally strong ups and downs in relative humidity favour the formation of condensation - and thus increase the risk of moisture damage.

Thanks to SeaDry, the relative humidity remains below critical values and condensation does not occur.

Solution: Joint development of the desiccant concept

After analysing the requirements, the ThoMar product manager in charge recommended the use of twenty SeaDry Hook desiccant chains 600 g. These should always be distributed as evenly as possible in the container and can be attached to the lashing rings by means of a sturdy hook. The amount of desiccant required was determined on the one hand by the expected day and night temperatures typical for the time of year (May / June) in the areas passed through. On the other hand, a safety buffer was necessary concerning the absorption capacity, as the transfer on the Silk Road can be considerably prolonged by the rerouting to other gauges as well as by waiting times in the customs area. It had to be ensured that the desiccants could keep the relative humidity at a non-critical level during the entire transport period.

The load is protected during transport not only by desiccants but also by dunnage bags.

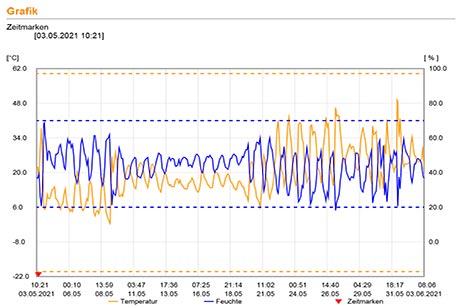

Result: SeaDry keeps your cargo dry

Thanks to the data logger used, the temperature and relative humidity could be precisely tracked. The progressions confirmed the precautionary measure of using desiccants during transport. The mould limit of 75% RH was not exceeded at any time, and on average the relative humidity was at an optimal 44.1%. The desiccant chains absorbed a total of 7.7 litres of water, about 60% of their own weight. Since the absorption capacity of SeaDry is at least 200%, there would have been sufficient reserves to ensure a longer transport time if necessary.

Evaluation of the data logger: Despite strong temperature fluctuations, the relative humidity during the experiment was only 44.1%.

Mould on Packaging and Packing Aids during the Transport of Machine Components

Challenge: Exceeded mould threshold and pre-contaminated packing materials

During the transport, the critical mould threshold was exceeded for extended periods. In addition, packaging materials and packing aids – particularly pallets and dunnage – showed elevated moisture levels and were already pre-contaminated before loading. The combination of these factors resulted in visible mould formation, making corrective action essential.

Solution: Combining suitable SeaDry container desiccants

Several SeaDry Pole H desiccant chains were evenly distributed and attached to the lashing rings inside the container, while compact SeaDry Single desiccant bags were placed inside the shipping crates. This setup ensured that the humidity level inside the container remained reliably below the critical threshold for mould growth.

Result: Long-term reduction of moisture damage and process optimisation

The use of desiccants prevented further exceedance of the humidity level at which mould develops. Visible moisture-related defects, such as darkened areas on the wood, were virtually eliminated. In addition, the company optimised its shipping preparation processes: for example, it now consistently uses kiln-dried wood, which has resolved the mould issue in the transport of machine components once and for all.

As a partner on equal footing, ThoMar supports its customers with decades of expertise in moisture control, transport logistics and desiccant technology – ensuring optimal results with cost-efficient solutions.

Mould formed on the packing aids

Metal industry: Preventing Corrosion on Steel Coils

Challenge: Leakage from drip-based systems and increasing corrosion risk

A shipping company specialising in inland waterway transport had already begun addressing the risk of moisture damage. Initially, the company opted for a drip-based desiccant system. As the name suggests, this type of system releases liquid during the dehumidification process. During one transport, this saline solution leaked and created ideal conditions for rust formation on the metal coils.

Corrosion on metal coils

Solution: Leak-proof moisture binding with SeaDry

The container desiccant SeaDry, developed by ThoMar, is based on a salt–binding agent formulation. In addition to calcium chloride, starch is added to bind the absorbed water. The salt extracts moisture from the surrounding air, while the starch ensures that the resulting liquid is bound into a gel. This prevents any leakage and allows the saturated desiccants to be disposed of easily.

For a test run, the customer received precise instructions on how to deploy SeaDry together with data loggers and how to evaluate the results upon arrival. The relative water absorption capacity of SeaDry is ≥ 250% under real conditions over more than 60 days and ≥ 300% under extreme conditions ⓘ – significantly more than the approximately 125% of pure drip systems. This makes SeaDry not only safer but also more economical in use.

Result: Effective corrosion protection and economic benefit

The use of SeaDry resulted in a marked improvement in humidity control inside the container. No leakage occurred, humidity levels remained stable, and the steel coils arrived at their destination free from new rust formation. The combination of higher absorption capacity and leak-proof gel binding provides customers with a double advantage: maximum product protection alongside reduced usage and lower costs.

Corrosion and Musty Smell within Vehicles

Challenge: High humidity inside the vehicle cabin and container

Data logger analyses showed that relative humidity levels inside the vehicles reached up to 80 % during transport, resulting in odour formation within the cabin. At the same time, the critical corrosion threshold was repeatedly exceeded inside the container, encouraging flash rust and further corrosion on metal surfaces.

Solution: Combination of SeaDry desiccant chain and desiccant packet

Based on the measurement results, ThoMar recommended a two-step approach: inside the container, the SeaDry Strip ADH desiccant chain was installed to reduce humidity throughout the container space. In addition, a compact SeaDry Single desiccant packet was placed inside each vehicle to specifically absorb humidity within the cabin.

Result: Odour-free interiors and reduced corrosion risk

Following implementation of the desiccant solution, no further complaints were received from recipients. The vehicles arrived without musty interior odours, and the corrosion risk inside the container was significantly reduced. The combined use of SeaDry Strip ADH and SeaDry Single proved to be a highly effective moisture-protection measure for vehicle transport in containers.

Photo composition: Car in container

Protecting Fixture Components for Automotive Manufaturing from moisture

Challenge: Protecting Electronic Components During Sea Transport

Structural plates containing sensitive electronics react even to moderate humidity. During the long container journey, there was a risk of condensation, corrosion and mould growth – both on the components themselves and on the wooden export crate.

Solution: Combination of DIN-Certified Desiccants and High-Performance Desiccant Blankets

In close coordination, the customer packed the structural plates in a customised aluminium barrier hood, heat-sealed and equipped with DIN 55473 desiccant bags. In addition, SeaDry Blanket desiccant covers were placed on top of the barrier film to prevent potential mould formation on the wooden export crate. ThoMar supplied the required desiccants, advised the customer on the appropriate barrier film and arranged the corresponding procurement contact.

Result: Safe Delivery Without Moisture Damage

Thanks to the combined protective measures, the structural plates arrived at their destination free from moisture or mould damage. The packaging solution ensured reliable, all-round protection for the materials, electronics and export crate.

Clamping device for vehicle construction in export packaging

Preventing Corrosion on Chemical Drums

Challenge: High humidity and unfavourable loading conditions

Humidity inside the container increased not only due to climatic fluctuations, but also as a result of damp pallets and loading operations carried out in the open air. This led to so-called “container rain”, which further accelerated corrosion processes.

Solution: A combined use of suitable container desiccants

To reduce humidity levels, SeaDry Blanket desiccant blankets and SeaDry Single packets were initially deployed. At the same time, the customer optimised their logistics processes: pallets were stored in dry conditions and loading was carried out under weather protection.

Result: Corrosion prevention and reduced desiccant consumption

The measures effectively prevented corrosion on drums and seals. Thanks to improved storage and loading conditions, subsequent shipments required only the use of SeaDry Blanket – eliminating the need for additional SeaDry Single packets entirely.

Photo composition: Chemical drums in sea container

Mould after Shipping Cornstarch Sacks

Challenge: Residual moisture in the product and condensation in stretch-wrapped pallets

The analysis showed that the production-related residual moisture in the starch led to the formation of condensation inside the stretch-wrapped pallets. With no possibility for air circulation, humidity accumulated on the surface of the sacks – creating ideal conditions for mould growth.

Solution: Targeted placement of SeaDry Blanket and SeaDry Single

The stowage plan and the container loading process required a desiccant solution that could be positioned directly on top of the bagged goods. The customer opted for the SeaDry Blanket desiccant sheet. In addition, the top cover film on the pallets was removed to allow better air circulation. The customer also placed SeaDry Single desiccant bags in gaps between the sacks to reduce humidity directly within the pallet packaging.

Result: No further moisture damage during transport

The combination of desiccant sheets, additional individual bags and optimised packaging processes enabled effective control of moisture and condensation. Since implementing these measures, no further mould or odour issues have occurred during the transport of starch.

Photo composition: Starch sacks on pallets in freight container

Beverages: Sodden Cardboard Packaging

Challenge: Persistent moisture damage despite existing desiccant use

Daily temperature fluctuations inside the container repeatedly pushed humidity levels above critical thresholds. The analysis carried out by the ThoMar consultant also revealed that the specific packaging process further promoted condensation within the stretch-wrapped retail units. Attempts to counteract the issue by increasing the number of desiccants used proved ineffective – and with around 5,000 containers per year, significantly raised logistics costs.

Solution: Optimised desiccant placement with SeaDry Blanket and SeaDry Single

Together with the customer, ThoMar developed a procedure to use desiccants far more effectively. The in-house manufactured SeaDry Blanket was placed on top of stretch-wrapped pallets, complemented by flexible SeaDry Single desiccant bags positioned within the load. By adjusting the pallet packing scheme, moisture ingress could be reduced and the effectiveness of the desiccants significantly increased.

Result: Dry cartons, intact labels and improved cost efficiency

Following the implementation of the revised desiccant strategy, cartons and labels remained intact, and no further complaints from customs were received. The optimised use of SeaDry enabled a noticeable reduction in the amount of desiccant required – delivering high effectiveness alongside improved economic efficiency throughout the export process.

Photo composition: Pallets with beverages in a container

Protecting Sensitive Metal Parts from Corrosion during Storage

Challenge: Wide temperature fluctuations and maximum condensation risk

Throughout the several-month storage period (March to June), the container was exposed to direct sunlight and varying weather conditions. Data loggers recorded temperature swings from –2.2 °C to +43.9 °C – a critical range in which significant condensation would normally be expected. For the sensitive metal parts, this posed a considerable risk of corrosion.

Solution: Safe storage with container desiccants

To prevent moisture-related damage from the outset, the customer installed several SeaDry Hook 600 g container desiccant chains on the lashing points inside the container corrugations. At the same time, temperature and relative humidity were continuously monitored using data loggers.

Result: No corrosion despite extreme temperature variations

Despite maximum condensation conditions, humidity inside the container remained below the critical corrosion threshold throughout the storage period. The average value was just 37.3 % relative humidity. This confirmed that SeaDry desiccants – originally developed for use in sea containers – also perform reliably in stationary storage, even under extreme climatic stress.

Container as interim storage

Protection against Moisture in Temporary Storage for all Kinds of Goods

Challenge: High humidity and fluctuating temperatures in storage

In most self-storage facilities, there is no electricity, so heating or electrical dehumidifiers cannot be used. Without such climate control, the stored goods are exposed to fluctuating temperatures and humidity, which can lead to condensation and potential damage to the stored items. This is particularly problematic for sensitive items such as furniture, electronics, or textiles.

Solution: SeaDry container desiccants prevent mould, odours, and more

The simple and efficient solution: using container desiccants, such as SeaDry from ThoMar’s range. SeaDry is based on a blend of calcium chloride and starch, which absorbs moisture from the air like a sponge and securely stores it inside the desiccant bags. This helps prevent mould growth, unpleasant odours, and material damage caused by excess moisture.

Result: Optimal storage conditions through reliable protection against moisture damage

Using SeaDry desiccants provides reliable moisture protection, keeping your goods safe from moisture damage. With different formats and fastening options, SeaDry can be used flexibly in various storage environments and for different types of goods.

Self Storage Container Facility

Do you transport your goods by sea container or do you use container transport by rail via the New Silk Road? The most important thing for you, as well as every exporter, is that the load arrives at your client as a whole and in one piece, isn't it? Stretch wrap, lashing straps, anti-slide mats, and further packing aids are used when securing cargo. Still you can never be sure what nasty surprise awaits the person opening the container at the port of arrival. High humidity and extremely fluctuating temperatures for weeks on end throughout the trip can damage the goods themselves, their wrapping, and the packaging aids. That might as well be each carrier's nightmare.

Or do you use containers as additional storage space, permanently or temporarily? Even the temperature fluctuations between day and night can be enough to cause the humidity in storage rooms to repeatedly exceed a critical level. Mould, rust and changes in the smell or taste of the contents and packaging of the stored cardboard boxes, big bags or general cargo are the possible consequences, just as with container transport.

If you've just been confronted with the unpleasant follow-up of a transport or storage damage due to too much moisture, rest assured: You are not alone. It doesn't matter if you produce cars, machinery parts, or metal coils, if you brew or bottle beverages and liquors, or if you manufacture apparel or leatherware. ThoMar OHG recommends the use of a long-term effective dehumidifier based on salt and starch. The salt attracts moisture from the ambient air, which is then immediately bound to a gel by the starch and cannot escape.

Our high performance container desiccant SeaDry was originally developed specifically for the use in sea containers, but is also ideally suited for rail transport. Furthermore, it protects stored goods against moisture damage. Clients from various industries, e.g. machine construction, automobile manufacturers, or the food industry, trust in the performance of SeaDry made by ThoMar. We provide solutions, not only products.