Desiccant calculator: What factors need to be taken into account?

Many different factors play a role in calculating the right amount of desiccant required. The following list is intended to give you an initial overview of the information that is basically necessary for this. A reliable desiccant calculation for your specific application, which is at the same time safely effective and also economical, can only be made within the framework of an individual consultation. You are very welcome to contact us without immediate obligation. We will gladly answer any questions you may have.

1. Barrier layer

Desiccants protect your goods by reducing the humidity. The dried air must not be allowed to become more humid by supplying more and more new air. A barrier layer is therefore necessary to limit the air exchange. Wood and cardboard do not limit the air exchange sufficiently and are therefore unpredictable and not suitable as a barrier layer. Barrier layers of film around the packaged goods are common. When using overseas containers, the container can be the barrier layer.

- Container: The container is assumed not to be completely airtight. There is a small exchange of air through cracks, holes and opening the doors. However, large ventilation openings must be sealed with adhesive tape.

- PE film: A PE film should have a thickness of 0.2 mm (200 my). The thicker the foil, the less water vapour diffuses through the foil.

- Aluminium composite foil: Compared to PE foil, aluminium composite foil has a much denser barrier layer and is particularly suitable for long storage periods.

- Size of the packing space: The packing space is the volume of the space bounded by the barrier layer. While for the container it is necessary to specify whether, for example, a 20 or 40 foot standard container or a 45 foot high cube is used, when using PE or aluminium composite film the size of the packing space must be specified through length x width x height.

2. Climate during packaging

It makes a big difference whether the goods are packed and loaded or stored at around 18°C and 70% relative humidity or at 25° C and 90% relative humidity. When calculating the amount of desiccant required, we recommend starting from the most humid possible climate in order to provide optimum protection for your goods in any case.

3. Moisture content of the goods to be protected

The goods to be protected may also contain moisture that is released into the air. During temperature fluctuations, the moisture can condense on the surface of the goods and cause damage. It is therefore necessary to check whether the goods emit moisture.

- Weight of the goods

- Do the goods not contain water? This is the case with metal, for example.

- Is the product air-dry? This is based on a water content of max. 18%. Of this 18%, a maximum of 8% can evaporate and 10% residual moisture remains in the material. These are the values for e.g. dry stored wood and cardboard.

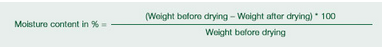

- Determine the moisture content yourself: Moisture meters can be used for an accurate check. It is also possible to weigh a sample piece, dry it in an oven at 60°C and weigh it again. The difference in weight corresponds to the amount of moisture that can evaporate. The calculation is made according to the following formula:

4. Packing / packaging aids

Packing and packaging aids are intended to secure and protect the goods. However, they can contain too much moisture. In this case, the moisture damages the goods to be protected during temperature fluctuations. Therefore, it is important to use only packaging materials that are as dry as possible. What and how much of it, apart from the goods, goes into the barrier envelope?

- Type of packing / packaging aids, e.g. pallets, cardboard, cushioning and securing material

- Amount / weight of the packing / packaging aids

- Moisture content (air-dry? own moisture measurement with the above formula?)

5. Transport climate / storage climate and duration

This approximate information is necessary to calculate the air exchange over time through the barrier layer.

- From which country to which other country will the goods be transported? Or - in the case of exclusive storage - in which country is it stored?

- Transport: Duration (loading to unloading date) incl. storage time at the starting point before dispatch and at the destination after dispatch

- Storage: How long should the goods be stored?

- Desired final moisture content: The calculation according to DIN is usually carried out with a desired final moisture content of 40%. It is of course possible to carry out the calculation for another target value as well.

Please note:

If the moisture content of the goods and / or packing / packaging materials is too high, the required quantity of desiccants increases undefinitely. In this case, supplementary measures are necessary to ensure the economical use of desiccants. Our team of consultants can also support you in process optimisation. Contact us - together we will keep your goods dry!