Desiccants or drying agents are hygroscopic granules, which means that they actively attract water or moisture from the ambient air and store it. The granules are usually filled in bags made of special materials. The bag material must protect the desiccant from contamination, but must also be permeable to water vapour in order to ensure the absorption of humidity. Desiccants can be used to directly influence the climate in an enclosed space, as the water absorption of the desiccant reduces the absolute and relative humidity of the air.

While the term desiccant is commonly used for industrial applications, the term dehumidifier has become established for home use. You can find out more about dehumidifiers in the FAQ section "Dehumidifiers for mobile and home".The "desiccant method" is used to protect products from moisture damage. This involves adding desiccant to a sealed envelope, the so-called barrier layer (i.e. an enclosed space), to protect the goods. The desiccant absorbs moisture from the air and in doing so lowers the relative humidity to a harmless level.

Desiccants are categorised according to their granulate composition. The different types of granules are all suitable for different purposes.

The most common types of desiccant are:

- Silica gel

Often packaged in the form of transparent pellets. Can store 25-39% of its weight in water, depending on quality. Silica gel, sometimes also called silicon dioxide, can be regenerated, but regeneration is rarely worthwhile due to the low cost of the material. Exceptions to this are specially impregnated silica gels for laboratories or test facilities. - Clay granulate-based desiccants

In Germany, clay is the most common desiccant material for shipping in relatively small volumes. Clay granules can store 30 % to 35 % of their weight in water. Clay granules such as bentonite are increasingly used in desiccants certified to DIN 55473, for example. - Salt-based desiccants

Salt-based desiccants can be categorised into drip systems made of pure salt and combination systems with binding agents. In addition to private household use, drip systems are used in particular for storage. As salts liquify, a brine is formed in draining systems, which can pose a risk to goods or surfaces if it leaks. Binding agents have been developed for this purpose, which bind the resulting brine and thus prevent it from escaping immediately after it has formed. - Molecular sieves

Molecular sieve is the functional name for synthetic zeolites (or other substances) that are characterised by a high adsorption capacity and fast absorption speed for certain gases, vapours or liquids. For this purpose, the pore diameters of the zeolite are adjusted to the size of the molecules to be absorbed (e.g. H2O / water molecules). Molecular sieves are used in many industries and systems.

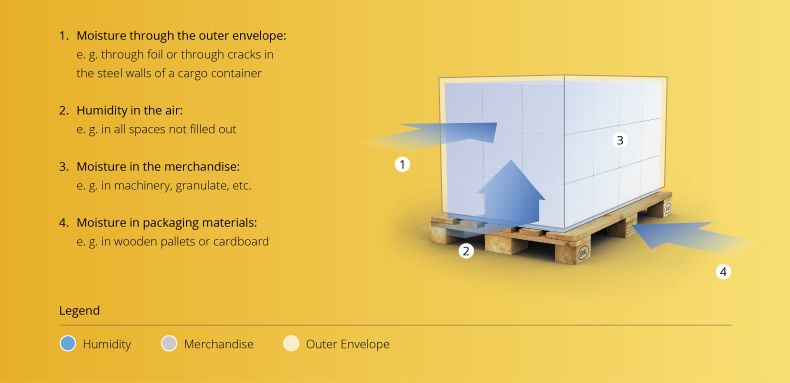

The following diagram visualises the various sources of moisture:

All four moisture sources must be taken into consideration to ensure correct dimensioning. In a closed system, moisture levels can be calculated precisely using formulas or estimated based on empirical values. Our customer representatives will gladly advice you.

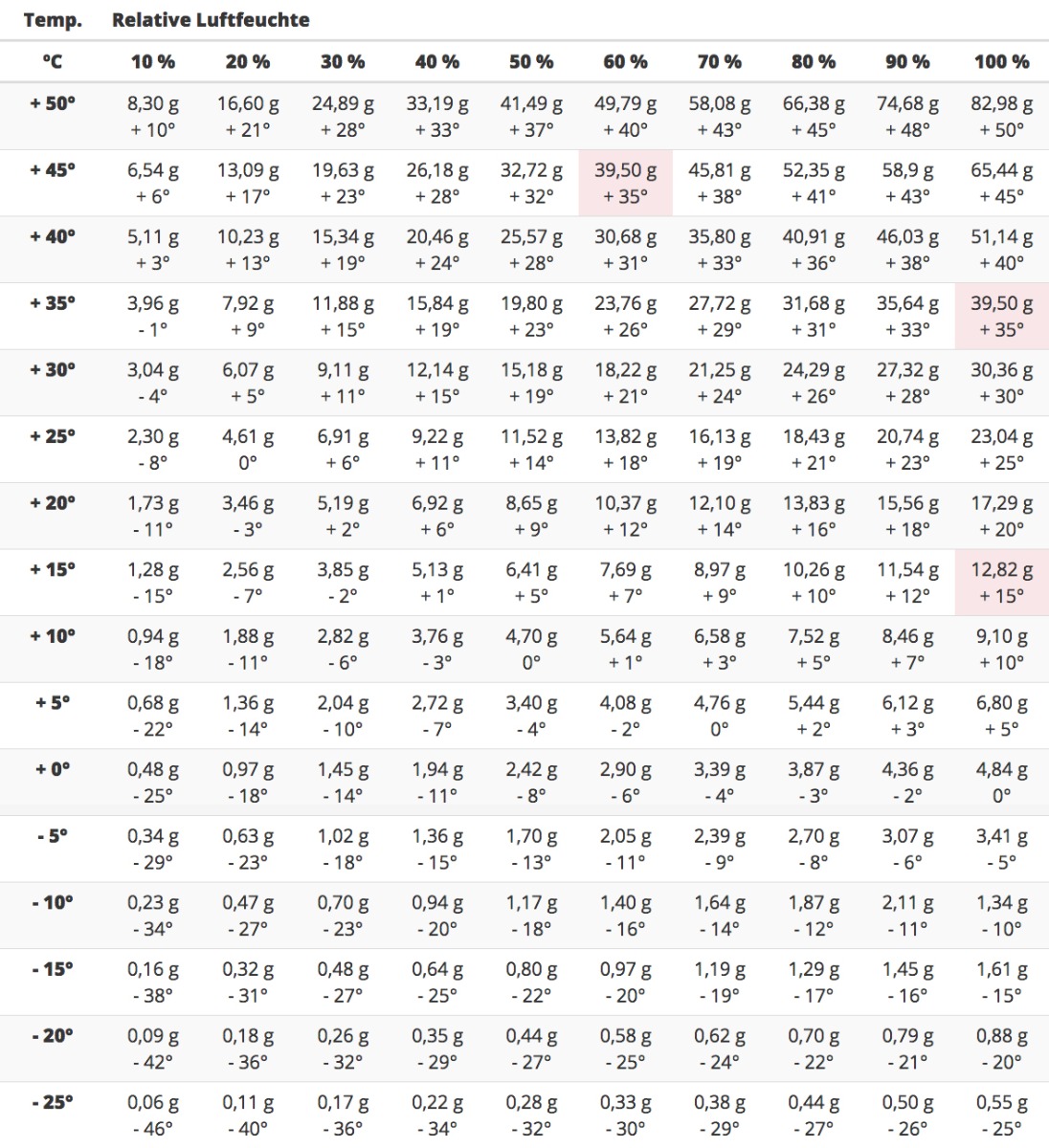

The air stores considerably more water at high temperatures than at low temperatures. The maximum adsorption capacity of 100 % is 30.4 g/m³ at 30 °C, but only 6.8 g/m³ at 5 °C. It follows, therefore, that if the temperature falls by 25 °C at constant absolute humidity of 26 g/m³, 20 g/m³ will be released. Given that the moisture cannot escape through the outer shell when the temperatures fall, it gathers in or on the products or the packaging.

Vice versa, the moisture escapes from the products or packaging into the air when the temperatures rise. This means, for instance, that while packing the goods in the warehouse, a damp pallet can cause the originally low relative humidity to rise from 30 % to 80 %. Transported goods are exposed to severe temperature fluctuations, and not just when moving through different climate zones. Merely the difference between a hot sunny day and the following night can produce temperature variances of more than 50 °C in transport containers.

Absolute air humidity describes the volume of water present in the air, expressed as grams per cubic metre. Absolute humidity does not depend on the temperature and provides information on the actual quantity of water vapour in the air.

In contrast, relative humidity is far more important for the shipment of products. Air can only accommodate a certain volume of water before becoming "saturated". This property is dependent on the temperature of the air: Hot air can hold more water vapour than cold air. This is where the relative humidity steps in. It represents the ratio between absolute humidity relative to the potential saturation volume and hence expresses how full the air is at a particular temperature. The temperature-dependence of relative humidity means that its value rises sharply when the temperature falls at constant absolute humidity, as the capacity of the air also drops at lower temperatures.

The following climate table illustrates this phenomenon. The table shows the water vapour contained in one cubic metre of air, depending on the temperature and relative humidity. The water vapour content present in the air is expressed in g/m³ in the upper row. The lower row shows the temperature of dew point in ºC.

Example:

1 m³ of air contains 39.50 g of water at 45 ºC and 60 % relative humidity. Cooling of this air to 35 ºC (dew point) produces relative humidity of 100 %. So the same volume of water in 1 m³ of air is equivalent to 60 % relative humidity at 45 ºC and to 100 % relative humidity at 35 ºC. The air will no longer be able to hold the water if the temperature drops further to 15 ºC. It precipitates on the products and the packaging, or is absorbed by them. Relative humidity remains constant at no more than 100 % at 15 ºC. Only 12.82 g of water can be held. The rest is absorbed by the goods or the packaging: 39.5 g–12.82 g = 26.68 g water.

Damages vary from good to good. Subsequent, you will find a selection of possible damages:

- Corrosion damage: ferrous products (machines, technical instruments or canned food) tend to corrosion at higher humidities. Corrosion limit from 40 % relative humidity.

- Mould: cargo or cargo securing organic origin, including unprocessed food, textiles, leather or wood and wood products tend to mould formation. Non-organic substances, like pottery may tend to superficial mould formation as well. Mould growth limit is at 75 % relative humidity.

- From 100 % relative humidity condensation occurs from vapour to water.

Consequences thereof may be: mould stains, collapsed cardboard packing, labels become detached or clumping and swelling of bagged goods.

If you want to know more about possible damages, please contact our customer service. Just send us a message via the contact form.

There are various factors to consider when determining the appropriate amount of desiccant. At the following site - Calculate desiccants - we have summarised the most important parameters for you. Of course, our customer service will be happy to answer any questions and help you choose the best possible desiccant for your application.

Cargo sweat is the condensation of liquids on the surface of any type of goods. This happens under the following conditions:

In direct contact between air and goods, the air temperature must cool below the dew point for condensation to form. This happens when the goods are cooler than the air and their temperature is at the respective dew point level of the air (max.). This effect is not only created when containers are transported from cold to warm areas or when a sea container that has cooled down overnight heats up again in the morning due to sun exposure. Even the temperature differences between night and day in Central Europe can be enough to cause condensation in a storage container.

Container sweat is the accumulation of condensate on the inside surface of the container, which usually occurs under the ceiling. Due to their surface tension, the deposits collect to form droplets, which eventually drip off due to their weight. The dripping of the water is referred to as container rain.

This effect is caused by the direct contact between a cold container wall and the warmer ambient air. If the air is cooled below the dew point temperature through contact with the surface, condensation forms. The temperature discrepancies required for this form during transport from warm into cold areas. The cooling of the container walls at sea in the evening can also cause this effect. And, as with cargo sweat, this effect can also occur in containers used as storage space if, for example, it is already almost 20 degrees during the day in spring, but temperatures still drop to just above freezing point at night.

Shipping with containers poses new challenges for the "desiccant method", which is described under "Basic knowledge". A higher air exchange rate than with in-box shipping, extreme climatic conditions and long transfer times require very efficient desiccants. The clay granulate desiccants previously known as container desiccants in accordance with DIN 55473 can only guarantee this to a limited extent. The amount of desiccant required to achieve a relative humidity of 40%, for example, would be uneconomically high. In addition, the desiccant becomes saturated after a few days - it can therefore already be saturated before the container leaves the harbour. After that, your goods remain unprotected.

Salt-based desiccants have been developed to meet the requirements of container transport, whether by sea or rail, and also for storage in containers. Salts are highly hygroscopic and can absorb immense amounts of water. A distinction can be made between two categories:

- mixtures of salt and a binding agent

- salt-drip-systems

Clay or starch are generally used as binding agents, with starch being many times more efficient. Our SeaDry is a high-performance desiccant for use during transport and storage in containers, consisting of almost pure calcium chloride and modified starch, which can be found here.

Salt-drip-systems consist of a salt depot with air access and a draining basin. ThoMar OHG does not offer draining systems for container shipping and advises against their use due to the high risk potential caused by the produced brine, especially considering the rolling and pitching movements of the ship.

Pay attention to the quality of the products on offer. Tests by independent institutes regarding water absorption capacity or absorption speed are good indicators of product quality. There are suppliers who claim that their desiccant can absorb over 350% moisture. Ask under what conditions (laboratory? real-life test?) this result was achieved.

The quality of the bag material used is also important for minimising the risk to your goods. A tear-resistant bag material should be used to prevent the desiccant from escaping at any time. Another important point, even if the bag material does not tear: How well does it trap the absorbed moisture? Particularly in the case of suppliers with very high performance promises, you should ask how liquidy the salt/binding agent mixture becomes after absorbing moisture and whether the fleece used is really leak-proof and can stop any drops of brine from penetrating.

ThoMar OHG recommends: In the end, don't compare prices per product, but the price per gram of water absorbed. The higher the quality of the product, the less handling effort, additional weight and risk for your goods.

You can find our product here.

In general, the shelf life of container desiccants depends on the packaging and its sealing. ThoMar OHG uses HDPE bags for packaging, which have a high water vapour barrier. The bags can also be resealed so that individual products can be removed if required. If stored properly, SeaDry can be stored for two years from the production date without any problems.

Using the list on the following URL - Calculate desiccants - you can collect all the relevant factors for your specific application. Our customer service team is always available to answer any questions and provide advice. Don't hesitate to get in touch!

- Desiccants should be evenly distributed in the container.

- It is recommended to position them as high as possible, since warm, moisture-laden air rises and the highest humidity levels are typically found just below the container ceiling.

- Look out for damage to the container shell, such as rust holes, cracks and doors that won't shut completely. If possible, seal these before using the container to transport your goods. Of course, this also applies if you want to store goods in a container or other type of large space without a hermetic air seal.

How long the desiccants stay effective, generally depends on the absorption rate and capacity of the desiccant used. These are largely defined by the surrounding climate.

Every substance, including a desiccant, always tries to achieve an equilibrium moisture content. The more moisture there is in a system, the more substances such as goods, packaging materials or desiccants absorb.

For example, a lower number of desiccants distributed in the container will generally absorb water more quickly and reach their maximum capacity faster, as the moisture is distributed over fewer materials. If more desiccant bags are used, the duration of their activity can thus be regulated. The different climates of the route as well as the loading and final loading climate also play a role here.

Follow the manufacturer's instructions for disposal. SeaDry, ThoMar's container desiccant, in normal market quantities should be disposed of as ordinary industrial residual waste.

Desiccants that are used inside packaging are also known as inbox desiccants. They are used inside product or transport packaging to bind moisture in the packaging space and prevent damage. ThoMar offers three solutions for this - Desi Dry, CertiDry and BoxDryy® - each of which is tailored to different requirements and packaging concepts.

Both the DesiDry silica gel bags and the CertiDry desiccant according to DIN 55473 with bentonite clay granulate are generally used within an airtight barrier layer - for example in combination with PE bags or films.

DesiDry is a proven standard among desiccants. The bags contain silica gel - an odourless, highly porous material based on silicon dioxide that effectively adsorbs moisture in the form of water vapour from the ambient air. The absorption capacity is around 30-40% of its own weight, i.e. around 300-400 ml of water vapour per kilogram.

BoxDryy® is the most high-performance desiccant in the ThoMar range. Inside the bag, a particularly efficient magnesium chloride active granulate ensures that the moisture absorption is significantly higher than that of standard desiccants. BoxDryy® can therefore be used without additional outer packaging or a barrier layer and is inserted directly into packaging units such as boxes or crates. The innovative combination of active ingredients is ideal for modern, sustainable packaging solutions with reduced material usage and efficient product protection.

These are standards that define the properties of certain in-box desiccants. DIN, standing for “Deutsches Institut für Normung”, is the German Industrial Standard, while MIL is the American equivalent. The technical pouch properties are almost identical. You can find further information on these standardised desiccants on the category page of CertiDry desiccants according to DIN 55473.

All desiccants according to DIN 55473 are directly comparable with each other, as the hygroscopic and absorption speed of the desiccant pouches are defined by the standards.

The letter after the DIN number refers to the dust permeability of the bag material:

In this regard, DIN 55473 defines type A - low-dust - as follows: "No more than 10 mg of dust may pass through the envelope per desiccant unit."

[DIN 55473:2015-12, 4.3.2 a) para 2]

And type B - dust-proof: "Irrespective of the volume of desiccant units in the pouch, no more than 1 mg of dust must be measurable following completion of the test."

[DIN 55473:2015-12, 4.3.2 b) para 2]

DU stands for desiccant unit and describes the amount of desiccant granulate that absorbs a given amount of water within a defined climate in a specified time.

DU is not an indicator for a certain weight of the desiccant bag. Depending on the quality and origin of the clay granulate, the weights of a DU may vary.

TME ist the equivalent designation in German. Depending on the origin of the desiccant, this designation may also be printed on the product.

Important: This information always refers to desiccants according to DIN 55473.

There are various factors to consider when determining the appropriate amount of desiccant. At the following address - Calculate desiccants - we have summarised the most important factors for you. Of course, our customer service will be happy to answer any questions and help you choose the best possible desiccant for your application. Just drop us a note via the contact form.

Just like the dimensioning, the use of desiccant bags is also regulated in DIN 55474.

According to the "Desiccant method" described under "Basic knowledge", the packaging must be supplemented with a barrier layer envelope. This is defined by its property of extremely low water vapour permeability. The barrier layer envelope must be tightly sealed and must not have any holes, tears or faulty sealing.

The desiccant bags are dimensioned in accordance with DIN 55474 and inserted directly before sealing the barrier layer envelope.

After opening the barrier layer envelope, the desiccants must be removed and replaced before resealing.

Industrial desiccants are not intended for regeneration. The cost of the required energy usually exceeds the cost of replacement by far. The exception here is bulk silica gel, which is used in laboratories and can be regenerated at approx. 130 °C.

These terms refer to the same systems and combinations of substances. In home use, the term dehumidifier has become established over the years, while the term desiccant is used for industrial applications.

In general, two systems can be distinguished:

- Adsorbent and absorbent systems

- Drip systems

Adsorbent and absorbent systems usually consist of silica gel, alumina / dry clay or salt mixtures. These bind the water physically or chemically.

Physical adsorption (substances/molecules adhere to the surface of another substance and accumulate there) is a reversible process. Such dehumidifiers can therefore be regenerated. These include our airdry car dehumidifier, Safe Dry dehumidier for cabinets and safes as well as Multi Dry universal dehumidifier.

In chemical absorption, e.g. water molecules penetrate the interior of a solid or liquid and mix with it. This process cannot be reversed, which is why absorbent dehumidifiers are disposable products. Our airdry Fun window defogger is such a product.

Drip systems consist of a salt depot with air access and a drip tray. The salt depot attracts moisture from the air and liquefies. The resulting brine drips into the drip tray. As there is a risk of the brine escaping when such systems are moved, ThoMar OHG recommends only using drip systems for immobile applications.

Drip systems are suitable for wardrobes, larders, safes, storage of caravans, cellar and storerooms or bathrooms.

The airdry cushions can be dried on a radiator for reuse. Place the cushion with the foil underside on the radiator and heat on a medium setting. airdry releases its moisture over a longer period of time, which can be days or weeks depending on saturation and heating.

The Classic, Vanilla Fresh and Ice Fresh product variants can be expected to dry to a weight of approx. 1.2 kg. With the airdry Duo product variant, a bag will weigh approx. 700 g after regeneration. The original (initial) weight cannot be regained by drying! Please do not attempt to dry the bags beyond the specified values. This can lead to material damage and destruction of the bag.

We recommend drying over a longer period of time on a radiator, as this procedure is less hard on the material.

Drying in an oven is possible; however, we would like to point out as a precaution that we cannot provide any guarantee for this type of drying.

To do this, you must first distinguish between two different types of ovens:

- If it is an oven that turns off automatically when you open the oven door a crack, then you should open the oven door from time to time during the drying process to allow the moisture to escape.

- If it is an oven where you can open the door without it turning off, then it is best to stick a wooden spoon or something similar into the gap and allow the moisture to escape this way.

The temperature during the drying process should be between 60°C and 80°C with convection. The drying process can take several hours. You should also wear heat-resistant gloves when removing the dehumidifier bag from the oven to avoid burns.

The airdry Classic, Vanilla Fresh, Ice Fresh and Duo product variants are not suitable for drying in the microwave.

It makes sense to use two airdry bags alternately. One dehumidifies the car, for example, while the other can slowly dry or regenerate.

Safe Dry can be dried on a radiator for reuse. To do this, take the dehumidifier pad out of the box and place the foil side on the radiator. Safe Dry releases the stored moisture over a longer period of time, which can be days or weeks depending on saturation and heating. Drying to a weight of approx. 330 g is to be expected.

We recommend this slow drying method as it is more gentle on the material. It is possible to dry Safe Dry in an oven. Please refer to the regeneration instructions for airdry car dehumidifiers (Classic, Vanilla Fresh, Ice Fresh, Duo).

Multi Dry can be dried in an oven (not a microwave!) or on a radiator for reuse. When drying in the oven, place Multi Dry on a rack at medium height and set the oven temperature to approx. 175°C. Higher temperatures can damage the bag fleece (there is no risk of fire, though). The drying process takes approx. 4-5 hours. If Multi Dry is dried on a radiator, the drying process will take several days.

Caution: There is a risk of burns if you touch the heated bag and especially the metal clip. Use oven mitts or protective gloves when removing Multi Dry from the oven.

- In the oven: The airdry SILICA GEL can be dried in the oven for reuse at max. 100 °C (convection). The cushion releases its moisture over a period of 2-3 hours. Open the door several times during drying to allow moisture to escape.

- In the microwave: Dry at max. 600 W for up to 8 minutes. If necessary, the drying process can be repeated after a 15-minute break. During the break, open the cooking cabinet door to allow excess moisture (steam) to escape.

Risk of burns: Please use heat-resistant gloves to remove the dehumidifier bags from the oven or microwave.

Risk of overheating: Never exceed the drying times and heat output.

Compared to conventional silica gel bags, BoxDryy® impresses with its significantly higher moisture absorption and particularly easy handling. While silica gel bags are usually only effective in combination with additional, airtight packaging, BoxDryy® does not require a barrier layer at all. It can be used directly in cartons or boxes, making an important contribution to more sustainable packaging solutions. Thanks to the special combination of magnesium chloride and starch, our high-performance desiccant BoxDryy® reliably binds the absorbed moisture into a solid mass and thus offers leak-proof protection.

Yes, BoxDryy® is suitable for indirect contact with food. The clearance certificate fulfils the requirements of European Regulations (EC) No. 1935/2004 and No. 2023/2006 as well as the German Food, Commodities and Feed Code (LFGB). This means that BoxDryy®, the most high-performance desiccant, can be used safely in packaging solutions where there is indirect contact with all types of food - for example during storage or transport in boxes or crates.

BoxDryy® supports sustainable packaging concepts by eliminating the need for additional plastic packaging or barrier layers thanks to its high dehumidification performance. In contrast to conventional desiccants, which usually require airtight outer packaging, BoxDryy®, the most high-performance desiccant , is inserted directly into the shipping or storage packaging. This significantly reduces the use of PE bags, films and other packaging materials. In addition, the simple handling saves time in the packaging process and optimises logistical processes.

A liquid absorber is a special mixture that is used to safely and efficiently bind escaping liquids. Especially when transporting or storing products containing liquids, an absorber such as LiquiDry protects against damage caused by leaks. As soon as liquid escapes, the active granulate contained in the absorber absorbs the liquid and converts it into a gel-like, leak-proof mass. This keeps the environment dry and reliably protects goods and packaging from moisture damage or contamination.

The ThoMar LiquiDry liquid absorber is optimised for use with aqueous liquids and achieves the best absorption performance in this area. These include, for example, water in the event of leaks in transport packaging, cleaning agents from canisters or bottles and similar liquid carriers, saline solutions in medical and laboratory environments as well as blood and urine in the context of sample dispatch or hygiene tests. LiquiDry® can also be used safely for other biological fluids - for example when transporting deceased persons.

The absorption capacity of a LiquiDry liquid absorber depends on its size and design. The superabsorbent granules contained react to escaping liquids in a matter of seconds and convert them into a gel that does not release any liquid, even under pressure. Depending on the liquid, LiquiDry can absorb many times its own weight: With distilled water, the absorption capacity is up to 250 times its own weight, while with a 0.9 per cent saline solution it is around 60 times. For optimum protection, the appropriate absorber bag should always be adapted to the potential leakage volume. Further information on available sizes and variants of LiquiDry is available in the ThoMar online shop.

No, LiquiDry liquid absorber are intended for single use. The water-soluble paper dissolves immediately on contact with liquid, while the granules bind the escaping liquid in seconds and convert it into a gel. After complete absorption, the absorber is used up and cannot be used again.

No, LiquiDry reliably seals absorbed liquids into a stable gel. Unlike a conventional sponge, this does not release any more liquid, even under pressure. The innovative gel formation thus ensures that moisture is permanently and securely trapped - even during prolonged storage or transport. LiquiDry liquid absorber therefore guarantee a dry, clean packaging environment and offer effective protection against leaks and moisture damage.