SeaDry desiccants also perform under extreme conditions down to –40°C

- Nov 18, 2025

How reliably do desiccants perform after being exposed to extreme sub-zero temperatures? Our SeaDry container desiccants were subjected to a stress test designed to simulate the strong temperature fluctuations that can occur during transport and storage. The results show why tested and proven quality is so crucial for protecting sensitive goods.

We regularly test our desiccants to ensure their performance under realistic and extreme conditions. One requirement set by the German Armed Forces, where our SeaDry container desiccants are listed, was that they must continue to function reliably even after exposure to very low temperatures.

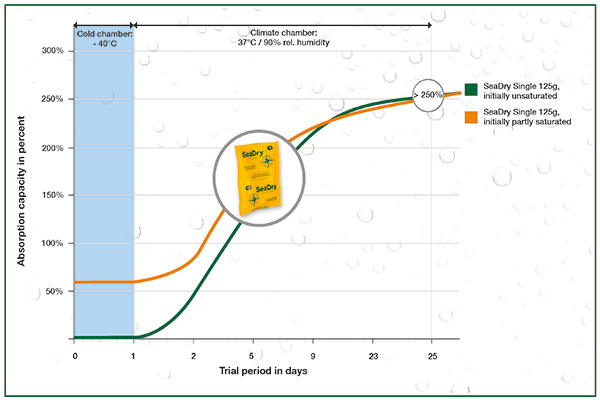

To verify this, a two-stage test was carried out:

- Test step 1: 24 hours at –40°C in a cold chamber at the BFSV Packaging Institute Hamburg

- Test step 2: 25 days at 37°C and 90% relative humidity in a climate chamber at ThoMar OHG

At –40°C, virtually no moisture uptake takes place because the air contains almost no humidity under such conditions. This phase therefore served primarily as a stress test to ensure that the desiccant remains fully functional after exposure to extreme cold.

Result: As the test graphic shows, the performance of the container desiccant is not impaired by extreme cold. Afterwards, the desiccant bags once again achieved peak values in moisture absorption.

With SeaDry container desiccants manufactured in Germany and certified to ISO 9001, you can reliably protect your goods from moisture damage during transport and storage – even in cold regions or during longer standstill periods in winter.